Managing the safe use of ammonia as a marine fuel

As ammonia gains traction as an alternative marine fuel, increasing attention is being given to the stringent handling requirements necessary for its safe adoption. Together with industry partners, also contributing with long-term experience in handling ammonia safely, DNV has developed a new recommended practice that provides a clear framework to support the maritime industry in this transition and ensure safe use at sea.

Low-emission ammonia is increasingly recognized as a viable alternative fuel with significant potential in helping the maritime industry decarbonize. Unlike conventional fuels, it has distinct characteristics that necessitate specific handling and safety protocols. However, with proper training and a well-established safety culture its use can be effectively managed.

“Ammonia is a chemical that deserves respect but should not be feared. This starts with a clear understanding of the hazard profile,” says Laurent Ruhlmann, HESQ Vice President, Yara Clean Ammonia. The company handles 20% of all globally traded ammonia, produces more than eight million tonnes of ammonia per year, and has a history of producing ammonia dating back to 1927.

Bridging the ammonia competence gap in maritime

“There is a lot of experience from handling ammonia on land for decades that can be easily ported over to the maritime world to help it meet the upcoming decarbonization targets,” Ruhlmann explains.

The maritime industry needs to embrace viable alternative fuels to successfully decarbonize. However, despite three ammonia-fuelled vessels already in operation and more than 30 currently on order (according to DNV’s Alternative Fuels Insight platform), specific training programmes for its safe handling as a marine fuel have been relatively slow to develop. This has created a growing competence gap, as existing training frameworks for alternative fuels like LNG do not adequately address the distinct properties and handling requirements of ammonia.

Maritime stakeholders shape ammonia safety practice

“Alternative fuel guidelines provide a strong foundation for safe adoption and handling, but ammonia requires a dedicated framework and strategy tailored to its specific properties,” says Erlend Erstad, Senior Consultant, Safety, Risk & Reliability at DNV Maritime Advisory. Together with industry partners, DNV has developed a recommended practice (RP) to provide shipowners, operators and regulators with the structured approach needed to ensure competence readiness for ammonia-fuelled vessels.

“DNV’s RP assists shipowners and training institutions as they develop new marine fuel programmes based on its guidance and with input to reviewed safety protocols, risk assessment frameworks and crew training requirements. It was developed with input from a number of key stakeholders including Amon Maritime, Azane Fuel Solutions, Yara Clean Ammonia, Wärtsilä, Kongsberg Maritime and Bernhard Schulte Shipmanagement/Ula Ship Management. This provided us with rounded and comprehensive best practice,” says Erstad, highlighting the benefits of close industry collaborations.

Learning from Yara’s leadership in ammonia safety

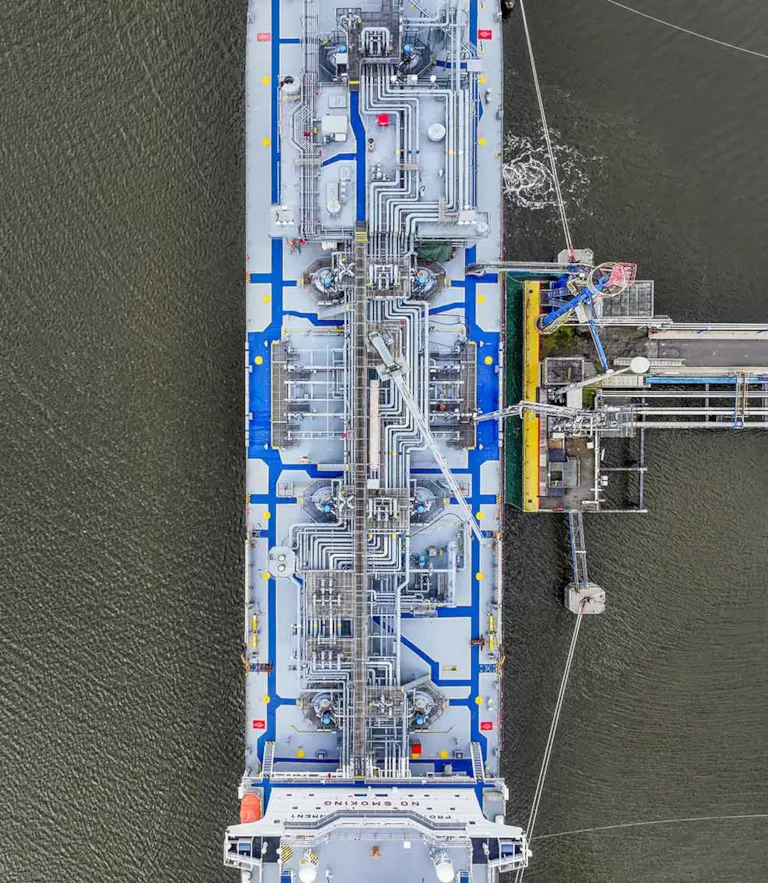

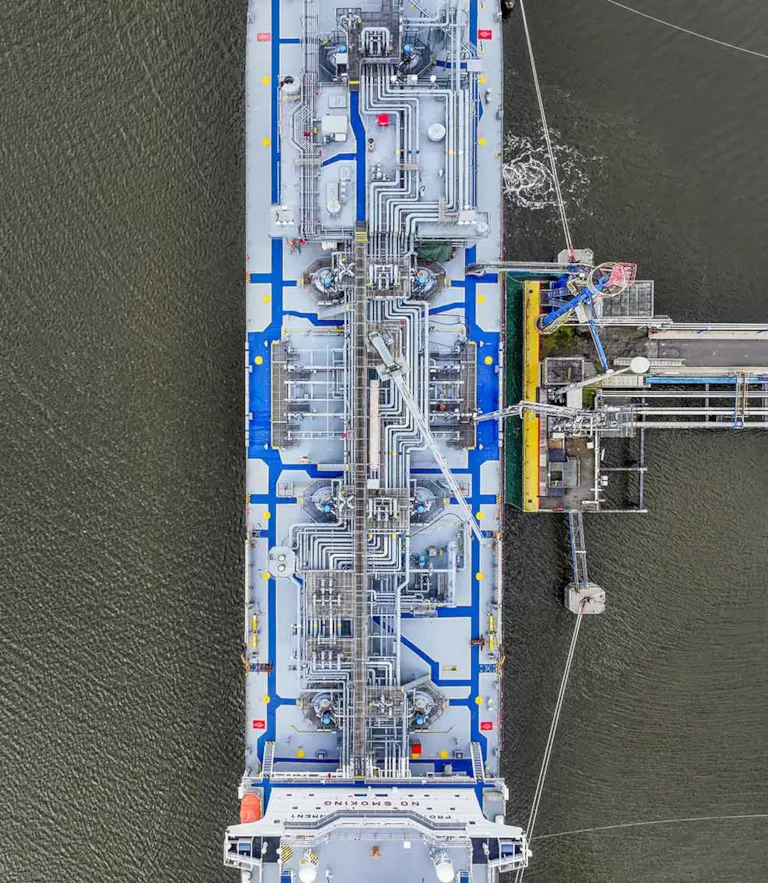

Yara Clean Ammonia was a key contributor to the RP’s development and has a strong safety culture. As a leader in ammonia production and handling, the company has decades of experience producing and transporting ammonia and operates the largest global ammonia network, with 15 vessels and access to 18 terminals worldwide.

Yara Clean Ammonia has already taken a final investment decision on Yara Eyde, which will be the world’s first ammonia-fuelled container vessel. The ship will transport goods between the Oslofjord area and other parts of northern Europe. Sixty per cent of the cargo will be Yara’s fertilizer products, thereby helping to reduce scope 3 emissions for Yara International.

“Yara Clean Ammonia’s extensive experience with the worldwide ammonia trade has helped shape the RP’s recommendations, particularly those regarding handling protocols, emergency response and risk assessment,” reports Kirsten Strømsnes, Business Development Leader at DNV Maritime Advisory. "The development of alternative fuels to replace heavy fuel oil (HFO) has been ongoing for decades, particularly since the adoption of gaseous fuels like liquefied natural gas (LNG). This extensive experience, along with insights from other industries such as Yara, gives the shipping industry an advantage in managing the safe use of ammonia as a fuel."

Ammonia growth: Safety key to drive future investments

Greater demand for ammonia as fuel could require expanding production, potentially doubling or tripling output within the next 20–30 years, making the need for specific ammonia fuel safety guidance even more urgent.

“Safety incidents could severely impact industry confidence in ammonia as a fuel. To mitigate this, human factors must be integrated with technical design from the outset, and both human and operational considerations should be prioritized throughout the vessel’s life cycle. Shipowners must ensure they have the necessary expertise on board and adhere to best practices from industries that have safely handled ammonia for decades,” Erstad emphasizes.

The transition to ammonia requires a shift towards a risk-based approach, Ksenia Zakariyya, HESQ Manager at Yara Clean Ammonia, says. “To ensure safe ship design and operations, dedicated risk assessments are essential for enhanced decision-making and the definition of technical, operational and organizational barriers to effectively control risks throughout the asset’s life cycle. Understanding ammonia’s hazardous profile is crucial for responsible handling. Ship operators must develop ammonia-specific competence and training programmes to address its unique safety requirements. Emergency response plans should be based on credible risk scenarios and tailored response strategies. Our experience demonstrates that with proper precautions in place, ammonia can be a safe marine fuel.”

The role of training institutions and flag states

With the RP, training institutions and the rest of the global maritime industry will now have a clear roadmap for developing concrete ammonia-specific training courses. The goal is to ensure that all crew members operating ammonia-fuelled vessels have the necessary competence for safe handling and use, ensuring that seafarers receive quality, standardized training that meets industry best practices.

The RP can also be used as input to competence planning and operational manuals as well as for reviewing safety management systems. It can also be used by third parties for certifying training programmes.

Flag states also have a key role to play as they currently need to approve the readiness of operations, including competence, before vessels with new fuels, following the alternative design approach, set sail. By endorsing the RP and referencing it in their guidance to shipowners, they can help drive the widespread adoption of ammonia safety standards in a more systematic way instead of case by case/vessel by vessel. This alignment will be crucial as the maritime sector moves towards integrating ammonia into global shipping operations.

Ammonia safety: What maritime can learn from the chemical industry

Yara’s Ruhlmann highlights that the chemical industry has had a strict regulatory framework in place for almost 50 years. This has supported a proactive approach in developing very robust safety management systems and practices which maritime can learn from and incorporate into its highly regulated framework. In the past decades, significant safety incidents with ammonia have occurred in its downstream usage where safety management systems and best industry practices are less developed. While onshore applications may face different challenges, the maritime industry has the unique advantage of being able to incorporate robust safety measures and recognized good practices from the very beginning when using ammonia.

“While ammonia presents certain challenges, shipowners and operators can confidently integrate it into their operations by implementing structured safety protocols, clear regulatory guidance and comprehensive crew training,” explains Ruhlmann. “Seafarers must receive ammonia-specific instruction, covering safe handling, emergency response and maintenance procedures. Regular simulated emergency drills and credible scenario-based training should also become standard practice to ensure operational safety and preparedness.”

The future of ammonia in maritime

“We need to be respectful of ammonia as a fuel and take the right precautions, such as building a proactive safety culture and being aware of small deviations and failures before situations develop into incidents. For many it is a different mindset, but we have to come around to using ammonia as a fuel,” Strømsnes concludes.

Regulations and safety frameworks will define the future use of ammonia-powered vessels. An industry-wide collaboration involving ammonia producers, regulators and vessel operators is critical for a safe transition, as shipowners will ultimately be responsible for implementing it aboard vessels as shipping complies with internationally agreed decarbonization targets set by IMO.

Erlend Erstad

Senior Consultant

Kirsten Birgitte Strømsnes

Business Development Leader - Safety

- Shutterstock / Sven Hansche

- Shutterstock / Dusan Petkovic

- Yara Clean Ammonia